Laboratory

We work carefully and pay a lot of attention to manufacture high-performance and reliable films

Our site includes a modern laboratory equipped with the analytical tools necessary to design, develop and control films: FT-Raman, Hot Tack, DSC, FTIR, Dynamometer, Peel Tester, COF Tester, Welder, MFI, Digital scale with measurement.

Raw materials

In order to provide customers with a high-quality film, we select the best raw materials, we carry out a first entry check and we monitor them throughout the manufacturing process so as to ensure traceability at any time.

Finished products

The quality control on the finished product is carried out by measuring the coefficient of friction of samples from the same batch in order to ensure the runnability of the product. Test results are recorded on our management system and contribute to define the consistency over time of the formulation. The batch samples, on the contrary, are archived.

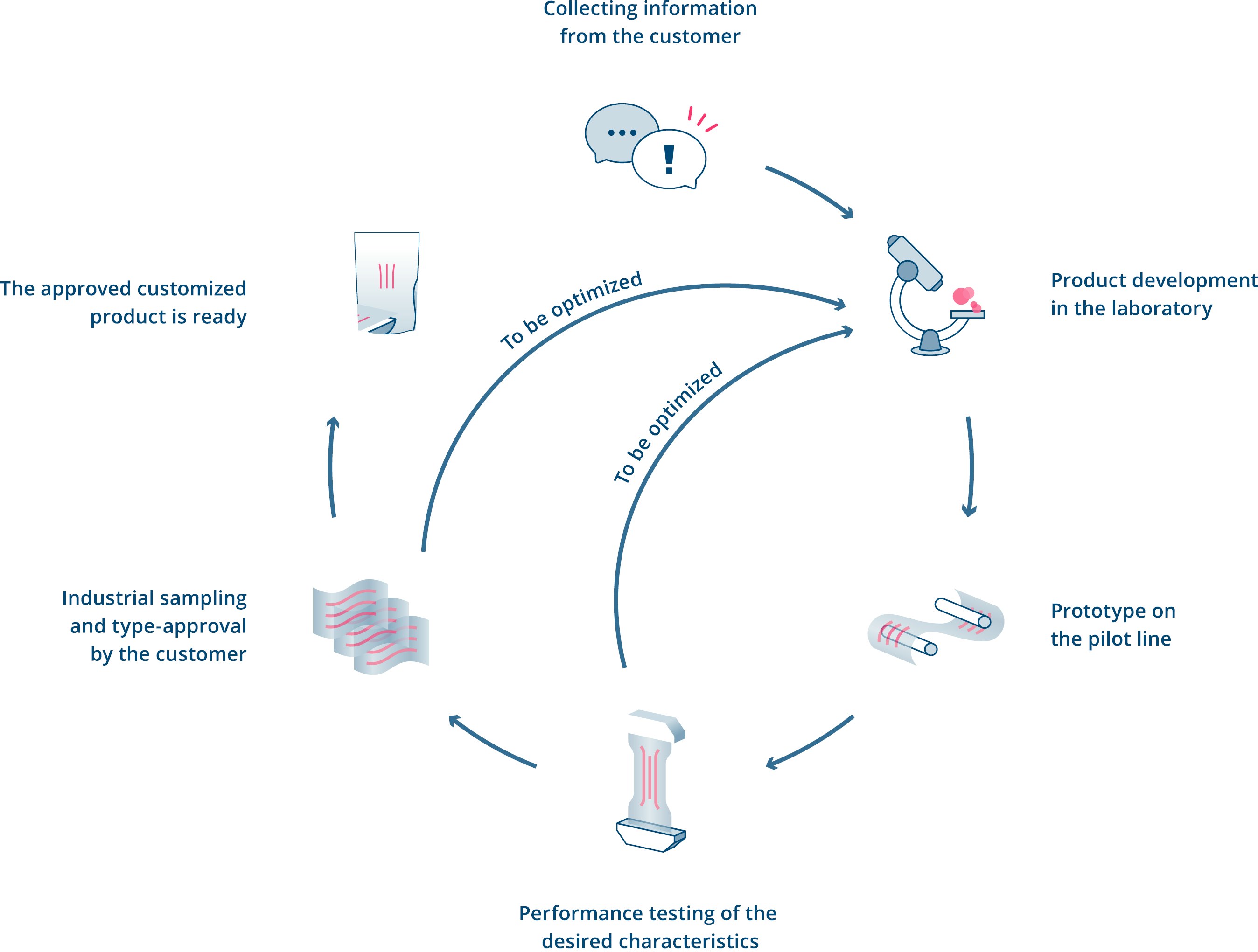

Are you looking for a special film? We can create the perfect film for you!

We can develop customized solutions: first we listen to the customer’s needs and then we get to the industrial application.

Call us!